📈 For investors

Invest in the seafood industry of the future – from Smøla

Smøla Seafood Export AS will establish a highly automated production line for processing salmon with the goal of exporting to the American market. With a strategic location in Smøla – close to the raw material and in the heart of Norway’s seafood – we are building a modern production facility with world-class technology and a clear goal of profitable growth.

We are seeking cooperation with investors who want to be involved from the start in a project with high execution capacity and great international potential.

🚀 Why invest in us?

- Lower tariffs to the US than the EU give us a competitive advantage

- Highly automated production reduces costs and provides scalability

- Strong demand for portioned, processed seafood in the US

- Robust technological expertise from the entrepreneurial team and industry partners

- Sustainable and local value creation, rooted in Norwegian raw materials and coastal culture

Business plan

Business plan for

Smøla Seafood Export AS

1. Summary

Smøla Seafood Export AS will establish a modern, highly automated processing plant for salmon in Smøla, with an annual capacity of 5,000 tons. Production will be directed towards the export market in the USA, where Norwegian salmon has a strong reputation and lower customs duties compared to the EU. Using advanced robotic technology, the company will achieve high efficiency and food safety, while creating 10–15 skills-based jobs locally.

The company was started by Bjørn Normann, who has a master’s degree in IT systems and extensive experience in software and hardware development. In collaboration with Walter Schaffhauser, who runs a robot factory in Germany, the company possesses the technological expertise required to build and operate a highly automated processing factory. Walter Schaffhauser will become a significant shareholder once operations are established.

2. Business idea

Smøla Seafood Export AS will produce and export processed salmon with high quality and traceability. The products will mainly consist of filleted, vacuum-packed and portioned products adapted to the US market. By using robotic production technology, we will reduce staffing requirements, increase production efficiency and ensure consistent quality at all levels.

3. Objectives

Establish a production facility with a capacity of 5,000 tons of salmon within 4 years.

Create 10–15 local jobs with a focus on technology and professional expertise.

Achieve an annual export share to the US of at least 1,500 tons within the third year of operation.

Become a leading player in robotic seafood processing in Norway.

4. Market analysis

The US as a target market:

Norwegian salmon is already established and in demand.

Lower tariffs on processed products from Norway than from the EU.

Increased demand for portioned and easily prepared products.

Competition:

Compete with large players such as Mowi and Lerøy.

Our niche is highly automated, flexible production and fast delivery.

5. Production and technology

The plant will be built with modern production lines where filleting, packing and labeling are done using robots and automated processes. We will use machine vision and sensors to ensure consistent quality and traceability. This provides:

Reduced need for manual labor.

High capacity with low waste.

Better hygiene and safe food production.

The production equipment will be modular and can be expanded if demand increases. The expertise of the project team and the partnership with a robot manufacturer in Germany provide a solid foundation for technological success.

6. Organization and staffing

With robotic operation, the following staffing is planned:

4–6 production operators/line supervisors

2–3 technicians for maintenance and robot operation

1–2 engineers for automation and IT

2–3 people for administration, logistics and sales

1 general manager/quality manager

The need for skills will be focused on technical education, and it is appropriate to cooperate with local educational institutions.

7. Sustainability and social impact

Creating jobs in the districts with forward-looking technology.

Local value creation: from the sea to the refined product at Smøla.

Reduced climate footprint through shorter transport of the finished product and efficient production.

8. Finance and investments

Investment needs rough estimate:

Factory building and infrastructure: NOK 40 million.

Production equipment and robots: NOK 30 million.

Working capital and start-up: NOK 20 million.

Total needs: approx. NOK 90 million.

Financing:

Equity from entrepreneur(s)

Innovation Norway and regional funds

Bank loans

Strategic investors

9. Risks and measures

Market fluctuations: long-term contracts and niche products.

Technology risk: collaboration with experienced suppliers and service agreements.

Currency risk: pricing in dollars and use of currency hedging.

10. Schedule

Milestone Date

Preliminary design and financing Q3 2025

Start of construction Q2 2026

Test production Q1 2027

Full operation Q1 2028

11. Appendix

Cost estimates for production lines

Market analysis USA

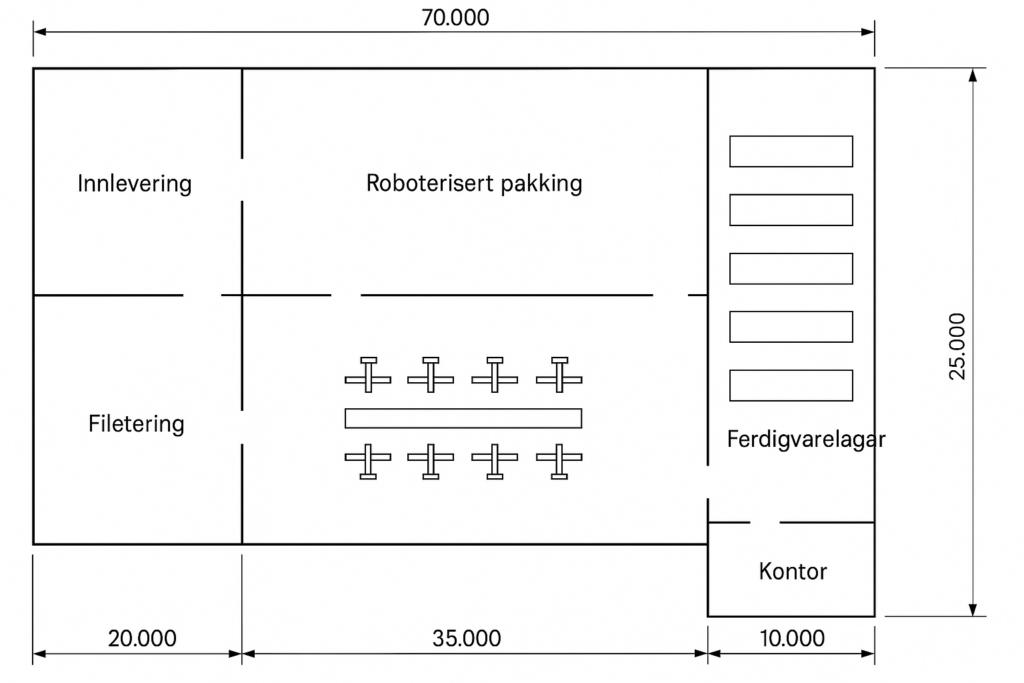

Factory layout sketch

.